UP-TO-DATE EQUIPMENT AND TECHNOLOGY

producing products with high quality and efficiency

Chekad Industrial Group is equipped with a wide range of up-to-date equipment and technology, which are used in the production process from design, molding to assembly. 60 to 1500 ton impact and hydraulic press machines, assembly lines, hanging welding guns and welding presses are part of this equipment.

Chekad has installed a complete system of machinery and industrial equipment in its production sites and is operating them in order to produce custom metal parts for its customers. These machines are made from the best brands and comply with global production standards so that we can produce the best parts with the least amount of waste and provide them to our customers. Also, according to standard control and repair systems, these devices are periodically inspected and periodically repaired.

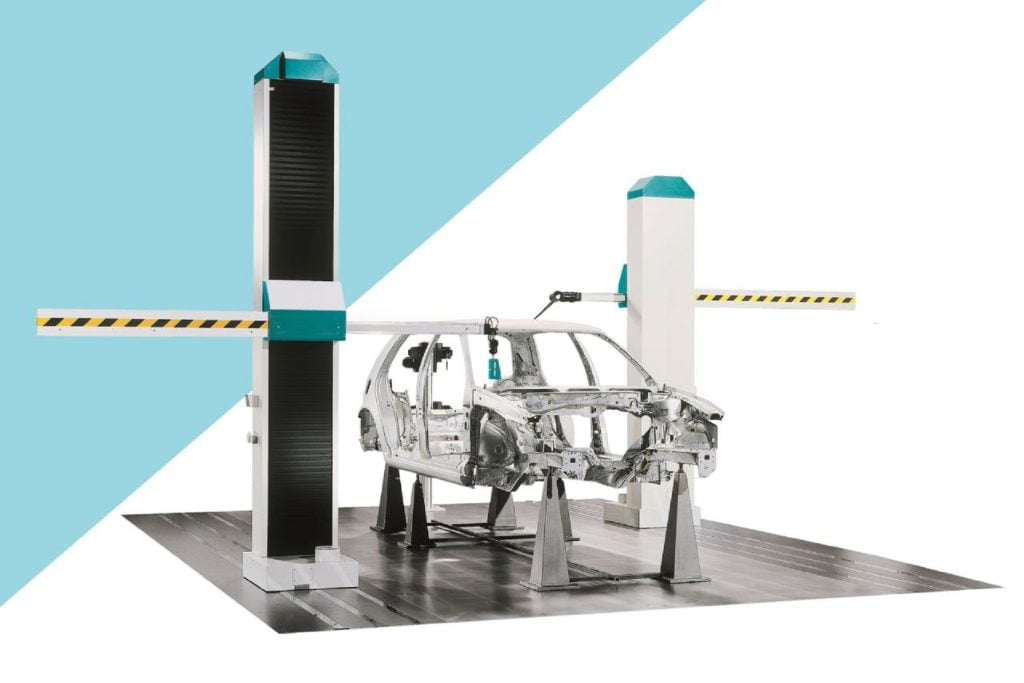

In line with its development plans, Chekad Industrial Group has purchased and launched WENZEL precision measuring device. This device has the ability to accurately measure car parts and equipment in large dimensions and scope and can eliminate the limitations in the measurement laboratories of various industries, including the car industry and parts manufacturing.

Also, in order to remove the limitation in the production of polymer parts, this company has purchased and set up a 4,000 ton polymer injection machine (for the production of large and integrated parts in the automotive industry and other industries). Engel’s unique device is able to overcome the existing limitations in the production of polymer parts in various industries of the country, especially the automobile industry.

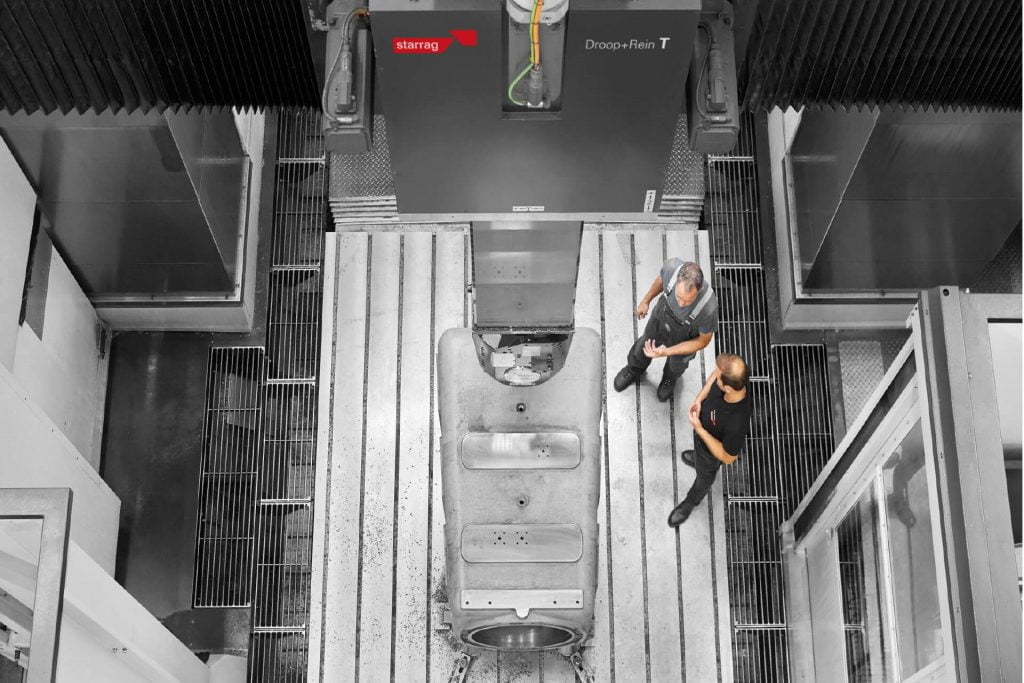

Chekad Industrial Group also has set up a molding site using modern Droop&Rein and MECOF equipment. Chekad is equipped with the largest machining and molding machines in the G1 and G2 category and will be able to provide services to the molding industry in the automotive industry and other industries.